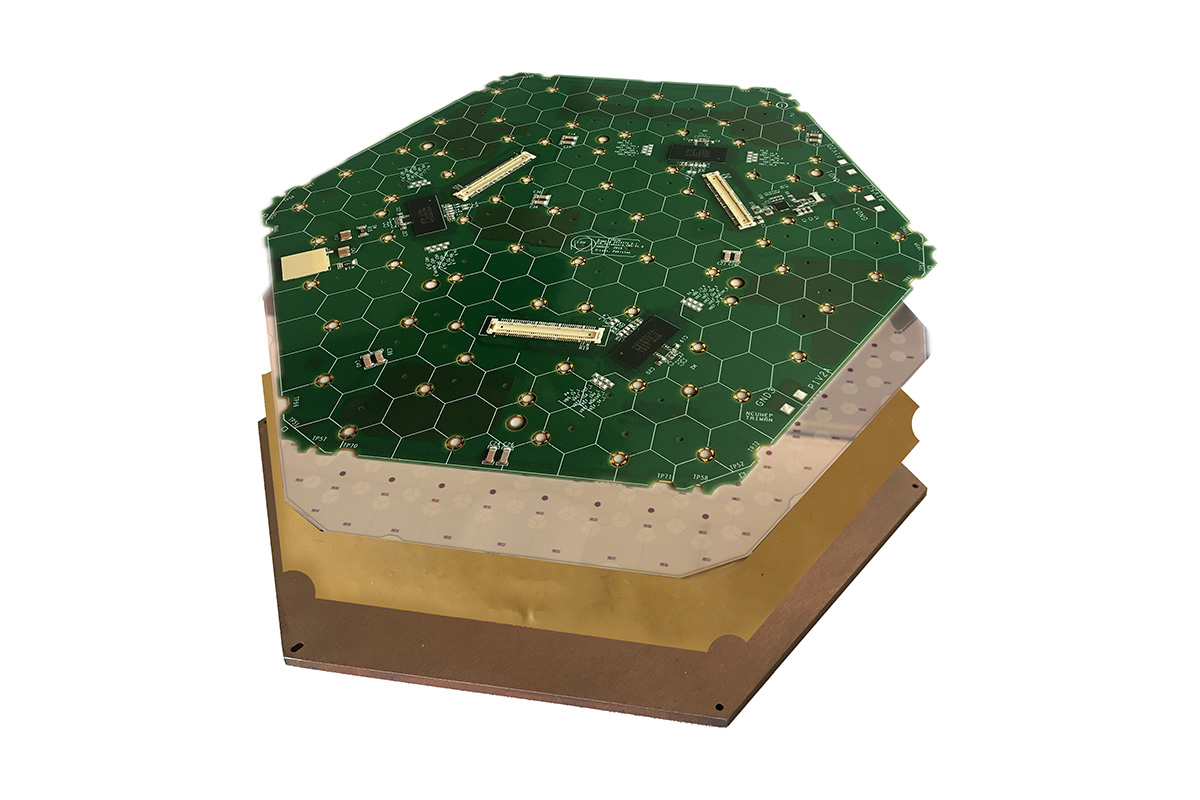

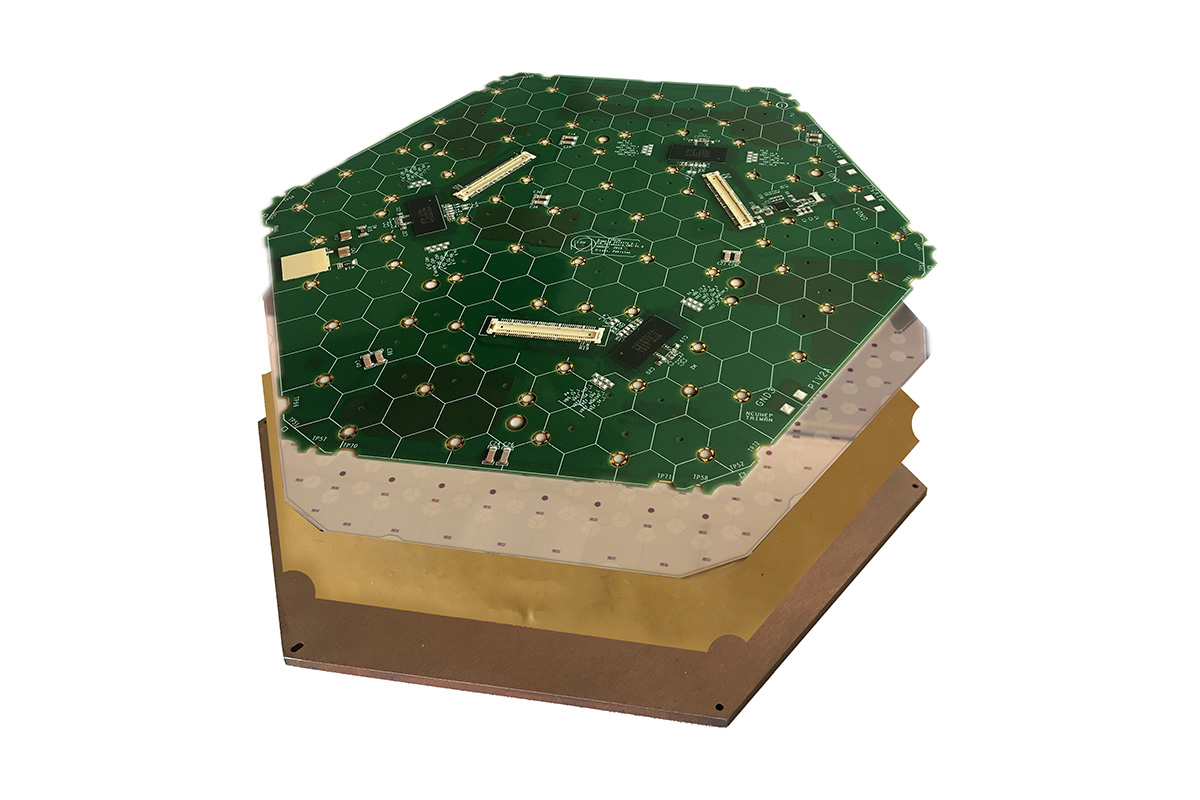

It’s eerily quiet on the main CERN site on the outskirts of Meyrin near Geneva, Switzerland. Only a few hundred people are present, a fraction of the 7500 who would usually be here. But today – Tuesday 21 April 2020 – is not normal at all. It’s the first time I’ve been back on site since CERN brought in COVID-related restrictions 40 days ago. I don’t plan to stay for long: I just want to collect 20 hexagonal printed-circuit boards (PCBs) that a company in Taiwan has manufactured and delivered to my office.

When I get back home, I’ll visually inspect the PCBs before sending them to a nearby firm to solder various components, including a custom-designed, radiation-tolerant prototype readout chip called HGCROC. We have a limited number of these HGCROC chips so before committing to soldering them (an irreversible process) I need to be sure the PCBs are all in order. I’ve therefore set up a makeshift lab on my dinner table, where a simple microscope is connected to my computer via USB (figure 1).

I need to look at fine details, such as the quality of the gold plating on regions that will have wires bonded for connection to silicon sensors, as well as macroscopic qualities such as the flatness of the boards. The microscope is a far cry from the professional equipment I normally use at CERN. But like all physicists, the COVID-19 pandemic has forced me to improvise and adapt. In fact, CERN’s staff, students, and users have been as active as ever during the lockdown; we’re just not all in the same place at the same time.

Calorimeter challenge

But back to those 20 cm-wide hexagonal PCBs. They’re first-of-their-kind prototypes, designed to read out signals from novel hexagonal silicon sensors onto which they will be glued. Eventually, around 30,000 similar PCBs, and their associated silicon sensors, will be required for a device called the High-Granularity Calorimeter (HGCAL). Set to replace the two “endcap” calorimeters of the CMS – one of the four giant experiments on the Large Hadron Collider (LHC) – the HGCAL will be installed during the third long shutdown of the LHC in 2026/27 (see the box “The Large Hadron Collider: still going strong“).

The new calorimeter is possibly the most challenging engineering project in particle physics to date, although the same could have been said about the existing CMS – and its companion detectors ATLAS, LHCb, and ALICE – when they were being developed more than 20 years ago. Indeed, the LHC has been pushing the boundaries of detector technology for decades – and will continue to do so for at least the next 20 years. That’s because its detectors are always evolving, with components being regularly replaced or added.

When I began working on CMS as a CERN fellow back in 1994, the LHC and its experiments were expected to operate for about 15 years, starting from around 2005. However, CERN’s decision to upgrade the collider to form the High-Luminosity LHC (HL-LHC) will not only extend the facility’s lifetime until the late 2030s but also let it produce up to five times as many collisions per second as now. That’s great for physics but, in practical terms, the huge increase in collision rate will lead to more complex collisions and more radiation. CMS’s endcap calorimeters would simply be unable to cope.

Coping strategy

Take CMS’s electromagnetic calorimeter (ECAL), which – along with a separate, hadronic calorimeter – makes up each endcap calorimeter (figure 2). Measuring the energies of photons, electrons, and positrons with incredible precision, ECAL is made of transparent lead-tungstate crystals that do two things. First, being so dense, they cause incident particles to deposit energy – mainly through bremsstrahlung and pair-production – and thereby create a shower of secondary particles. Second, they scintillate, producing light in proportion to the number of particles in the shower, with the light detected by devices glued to the ends of the crystals. Dubbed a “homogeneous” calorimeter because it combines both functions in a single material, ECAL has been invaluable to the success of CMS.

Trouble is, lead-tungstate crystals lose their transparency when heavily irradiated, which reduces the amount of light that CMS can detect. How much radiation the crystals receive depends on where they are in CMS. In the central, “barrel” section, the radiation is relatively low and the light loss will be manageable so the crystals will still be used in the HL-LHC. But in the endcaps, there will be so much radiation that the crystals would go completely dark if retained in the upgraded collider, reducing the amount of light CMS can detect to virtually zero.

But there’s another issue that people working on CMS need to think about, which is that the HL-LHC will achieve more collisions per second than the LHC by increasing the number of protons per bunch. In fact, when the bunches collide we can expect up to 200 almost-simultaneous collisions (compared to about 40 today). Every “image” that CMS takes of collisions will therefore be more complex, meaning we’ll need detectors that are much more granular – a bit like upgrading the camera on your phone to have more pixels to get sharper pictures. The crystals we currently use in the endcaps have a cross-sectional area of about 3 cm by 3 cm, which is too coarse to distinguish closely spaced particles from complex HL-LHC collisions. What’s worse, there is just one layer of crystals so we gain no “longitudinal” information on how the showers develop (which can help to distinguish different particle types).

Any replacement calorimeter, therefore, needs two things. It has to be resistant to radiation and it has to have good transverse/longitudinal granularity. Unlike the existing ECAL, what the new HGCAL will do is to separate the particle-shower-creating and the signal-producing functions by having alternating layers of dense materials (for the former) and detection layers (for the latter). Known as a “sampling calorimeter”, HGCAL will have 50 layers of fine-grained sensors in each endcap, made up of a total of about 600 m2 of hexagonal silicon sensors in the higher-radiation regions and 400 m2 of the trapezoidal plastic scintillator in the lower-radiation regions.

The silicon sensors will be divided into individual hexagonal “pixels” with areas of either 0.5 cm2 or 1.0 cm2, with the finer granularity being used in the most challenging areas. The scintillating tiles, in contrast, will have lateral dimensions of a few centimeters. Despite being coarser than some particle detectors, such as the “trackers” that trace the trajectories of charged particles, this granularity is unprecedented for a calorimeter. Indeed, the HGCAL will be the most granular calorimeter ever made in high-energy physics. Thanks to the many layers – and the high granularity in each – we’ll be able to disentangle the complexities of HL-LHC collisions.

Integration, integration, integration

These active elements will, of course, need advanced electronics, such as the hexagonal PCBs I mentioned above, plus more than 400 tonnes of copper, lead, tungsten-copper alloy, and steel to produce the particle showers. We’ll have to cool the detectors to –30 °C by sending liquid carbon dioxide downpipes embedded in the copper, which will remove more than 100 kJ of heat generated by the electronics every second in each endcap. We’ll need control and read-out functions. And with HGCAL having to fit into a volume of just 60 m3 split equally between the two end caps, it’s clear that integrating all the components is perhaps the biggest challenge that the HGCAL team faces.

It will be worth it though as each of the HGCAL’s 50 layers will produce detailed 5D images of particle showers and interactions (the three spatial dimensions, plus energy and timing). The timing information will be particularly valuable: with about 200 proton-proton collisions occurring whenever proton bunches in the HL-LHC cross, the collisions will be less than 100 picoseconds apart. So knowing precisely when they hit the HGCAL will let us disentangle particles from different collisions. If, for example, four electrons are seen by CMS in one crossing, they could have been produced by four separate collisions (essentially background noise) or by just one (possibly from a Higgs-boson decay).

Until now, this timing information was not needed at the LHC, but the collisions in the HL-LHC will be so complex that we need to do everything we can to extract the signal from the noise. We’ll also need new software tools, many of which will be based on pattern-recognition and machine-learning algorithms. With the new hardware and software in place, CMS will be able, for many years, to make further precision measurements of rare phenomena, and to discover new phenomena within reach of the HL-LHC.

The Large Hadron Collider: still going strong

The LHC is around 100 m below ground and the collision points are the locations of the four giant particle detectors installed in excavated caverns. It’s been running almost continuously for the past decade apart from year-end stops and two long shutdowns. We’re currently in the middle of the second long shutdown, which is due to finish at the end of 2021 and physicists are still analyzing data from the three quadrillion (3 × 1016) proton-proton collisions that the LHC has produced since 2010. Those collisions included signs of Higgs bosons, the discovery of which led to Peter Higgs and François Englert winning the 2013 Nobel Prize for Physics.

Only a few tens of Higgs bosons had been seen when their discovery was announced in 2012 but many more have been observed since then, letting us explore its properties and how it fits into the Standard Model of particle physics. Many other fundamental physical processes have also been studied and, although no signs of “new physics” beyond the Standard Model have been seen, we know much better where not to look for them. Still, it’s getting ever harder to explore the remaining regions of the particle landscape, which is why we need even more collisions.

The LHC will continue operating until the end of 2024, by which time we should have doubled the number of collisions produced so far. But to help in the hunt for new physics, plans are underway to boost the “luminosity” of the LHC – the number of collisions per second – five-fold. This so-called “High-Luminosity LHC” will come online after the third long shutdown in 2026/7, with the upgraded machine set to run until nearly 2040.

The future is bright

Back at my dinner table, most of the PCBs look good, but a few have minor imperfections – which is normal for prototypes of this kind. I send the good boards off for component assembly and when they arrive back at CERN in July, I join some colleagues to set up a customized measuring system that can be operated remotely (figure 3). In typical CERN fashion, we’re a mix of nationalities (British, French, German, Pakistani, Portuguese, and Turkish), disciplines (from physics to electronic engineering), and ages (from students to experienced staff).

Functional and performance tests on the PCBs are ongoing but they seem to be working fine. We’re also examining a “full” hexagonal silicon module, comprising a silicon sensor and a previous variant of the hexagonal PCB glued together and stuck onto a tungsten-copper alloy baseplate. Aluminum wires, 50 μm in diameter, are ultrasonically welded to the PCB’s gold pads and to metallic regions of the silicon, connecting them together. Signals from the silicon (created by charged particles passing through) are transmitted by the wires to the PCB and on to the radiation-resistant HGCROC chips. Designed by our colleagues from the Omega group in Paris, the chips amplify, digitize, and transmit the signals to the outside world.

This extensive development and testing of the silicon-sensor modules is just a part of the HGCAL design work that will be required before we move to full production in 2022. The large-scale assembly will begin in 2024 while the HGCAL will be installed in CMS in 2026/27. In fact, if the silicon modules (and their scintillator equivalents) are the “sensory organs” of the HGCAL, the “circulatory” and “nervous” systems – the copper power cables and the optical fibers for controlling and reading the sensors – will be even more challenging.

Many of the ancillary electronics required to make all this work – such as radiation-resistant optical transceivers and high-efficiency DC/DC converters – are being developed by a CERN-led consortium. They will not only be used in the HGCAL but also in other parts of CMS and in the other HL-LHC experiments too. Fitting all the components into place will be a real puzzle for electronic and mechanical engineers given that, in terms of the density and complexity of components, each endcap of the HGCAL is like a 250 tonne, 30 m3 smartphone.

There is also the “brain” of the HGCAL to consider. This is the system of custom-designed electronics and software that will control the detector and process its data. As with all CMS detectors, much of this equipment will be physically near the HGCAL, but in a separate underground cavern. It needs to be close, as the system must decide very quickly – within about 10 microseconds – if something interesting has taken place. If that’s the case, and the data pass further tests, we store them to disc for subsequent, full-scale analysis; if not, the data are discarded forever. Again, much of the electronics are based on common platforms wherever possible, sharing design resources amongst many groups, for the benefit of many systems.

Over the last few years, we’ve made huge progress evaluating the performance of the HGCAL and proving its feasibility. A rigorous and regular review process, with independent referees, ensures that no stone goes unturned and nothing is forgotten. Detailed milestones for everything from the electronics and the mechanics to the safety systems keep the project on schedule and within budget. Despite COVID-19, the reviews have continued and have been “passed” successfully.

But we can’t relax. There’s still a lot more work before we can start mass-producing all the components, assembling them into sub-units, building larger modules (or “cassettes”) from them, adding services, and then installing everything into the full-scale detector, before installing it into the CMS in around 2026. Then, of course, there’s the small matter of having to commission HGCAL and run it for 10–15 years.

more recommended stories

Texas Medical Board Releases Abortion Training for Physicians

Texas Medical Board Releases Abortion Training for PhysiciansKey Takeaways Texas Medical Board has.

Safer Allogeneic Stem Cell Transplants with Treg Therapy

Safer Allogeneic Stem Cell Transplants with Treg TherapyA new preclinical study from the.

Autoimmune Disorders: ADA2 as a Therapeutic Target

Autoimmune Disorders: ADA2 as a Therapeutic TargetAdenosine deaminase 2 (ADA2) has emerged.

Kaempferol: A Breakthrough in Allergy Management

Kaempferol: A Breakthrough in Allergy ManagementKaempferol, a dietary flavonoid found in.

Early Milk Cereal Drinks May Spur Infant Weight Gain

Early Milk Cereal Drinks May Spur Infant Weight GainNew research published in Acta Paediatrica.

TaVNS: A Breakthrough for Chronic Insomnia Treatment

TaVNS: A Breakthrough for Chronic Insomnia TreatmentA recent study conducted by the.

First-of-Its-Kind Gene-Edited Pig Kidney: Towana’s New Life

First-of-Its-Kind Gene-Edited Pig Kidney: Towana’s New LifeSurgeons at NYU Langone Health have.

Just-in-Time Training Improves Success & Patient Safety

Just-in-Time Training Improves Success & Patient SafetyA study published in The BMJ.

ChatGPT Excels in Medical Summaries, Lacks Field-Specific Relevance

ChatGPT Excels in Medical Summaries, Lacks Field-Specific RelevanceIn a recent study published in.

Study finds automated decision minimizes high-risk medicine combinations in ICU patients

Study finds automated decision minimizes high-risk medicine combinations in ICU patientsA multicenter study coordinated by Amsterdam.

Leave a Comment